How to Connect Multiple LED Strip Lights

We can connect multiple LED strip lights with each other depending on the power output of strip and the power source. These LED lights can be easily connected using various connectors, cables and also by soldering some joints.

We can connect two LED strips with each other very easily, if they come as reels with dotted (marked) lines to cut the strip lights into the required sizes.

Then, there are two ways to join strips. One is to use connectors or the other option is soldering some joints.

We can also connect different brands of LED strip lights with each other, provided that they must have the exact same voltage. If we try to connect two light strips with unequal voltages, then they will not work because of different voltage needs for each light strip. There is also a risk of damaging them; so a total wastage of money.

Polarity alignment should be proper when we connect them. Light strips of different brands may have the polarity wired in a different manner, so we need to make sure that the positive connectors are properly aligned. We should see a + and – symbol near copper pads for knowing exact direction.

One more important point is that different brands of LED strips may also be of different quality. If we want to connect LED strips of different brands, we may find that one strip wears out faster or started to dim. That’s why it is always safe to connect LED strips of same company.

Safety Tips

To ensure safety, we should always buy certified products with top quality. Cheap LED strip lights connected in series use very thin material that can’t bear high current levels and tend to heat up quickly. It can cause fire too. If we use an authentic and branded product, then also, we should take care of following –

- If we have some different types of LED light strips that need to be connected, then we should consider their all differences.

- The PSU & LED strip voltage has to match. We cannot connect all strips with each other as they cannot run with the same source of power. If our LED light strip needs 5 VDC, Power supply needs to be 5 Volts DC. The same concept applies for 12 Volts and 24 Volts LED strips.

Other than safety, we must use the most efficient and affordable way to power our connected strips. To connect LED strips into a single line and then looping it back with the start point so as to cover a rectangular ceiling is absolutely not the most effective technique. Best approach is to place a PSU on one corner of a rectangular ceiling and then connecting two LED light strips in parallel to the power supply. In this way, each strip will run along two sides of the rectangle, and both will be ending on the opposite corners of the PSU.

How To Connect LED Strips Using Connectors:

Depending on our requirements, there are some connector types available that we need to use. First one is – ‘Simple connector clip with pins’ which is used to connect continuously running LED light strips using the copper markings. These connectors are great when we need an invisible connection. They are available in different types of shapes to choose from based on our needs for strip crossings and styled corners.

The other option is a connector having 2 clip pins on both sides with a cable in between, which is used to extend 2 LED light strips with an extra cable to use around angles/corners.

Third is the connector with a wire. It will be the best option to bypass the obstruction, If we have the heating pipe in the room.

Fourth option is a connector which has only 1 clip on one side and has an exposed wire on second side with a cable in middle is used to connect LED light strip to PSU. On the other hand, we can use it for connecting with the RGB controller and with PSU to remotely control the overall setup.

How To Connect LED Strip Lights Without a Connector?

We can also connect LED light strips without using a connector by soldering some joints. We need to use soldering irons for this purpose. These type of connections can be considered precisely sturdier and have the ability to bring more productivity through extensions. If we are using heavy current, then it is recommended to solder the connections. Just after soldering, we should cover it with heat recoil for the protection of joints or we can use electrical tapes to cover them.

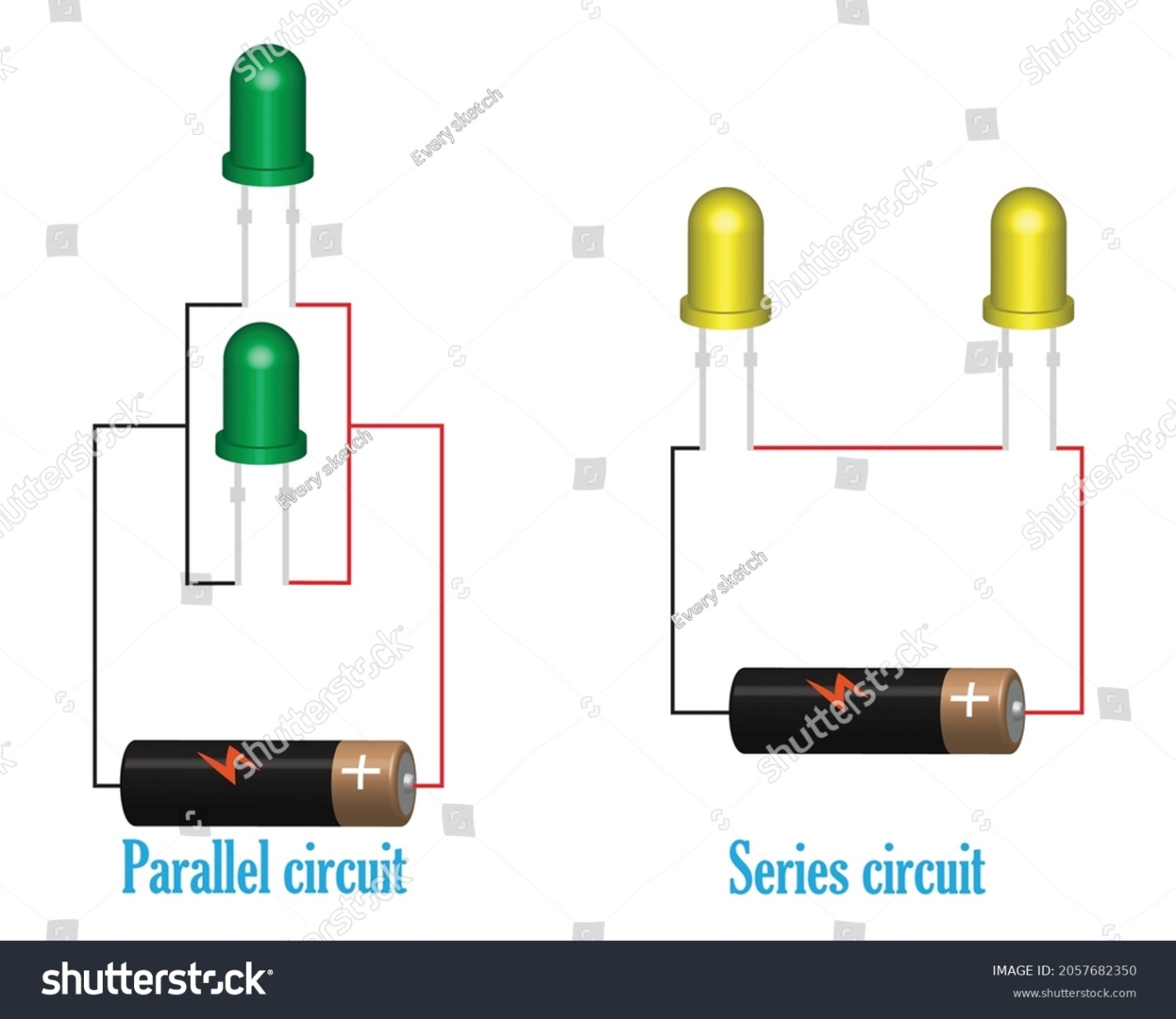

Connecting LED Strips: Series/Parallel?

As we know that, a series circuit has light strips connected end-to-end and the PSU will be directly connected into the very first LED light strip in the line. The current will be constant and the voltage will be divided equally between the LED light strips. Therefore, we may not get the equal brightness everywhere in the circuit and the PSU should be of a constant current. At the same time, if any one of the strips in our series fails, the complete circuit will force to stop work.

On the other hand, a parallel circuit has each light strip wired to the PSU and the current is splitting between each of the light strip, with equal voltage. It is harder to install first time, but if any one of our light strips fails, the other strips will always stay working. If we connect many light strips, then it will not be a problem. Still, if we are using a parallel circuit for only two light strips and when one fails, the current got doubled for the other strip, which can cause fire.

So, the conclusion is – If we want a consistent and uninterrupted lighting, then a series connection can be considered to be best. On the other hand, for typical circuits with multiple LED light strips, a parallel circuit will stay in partially working condition if one of the strips fails.

What To Keep In Mind While Connecting LED Light Strips:

We should keep below points in mind before starting our lighting project. Below are some key points –

- While connecting multiple LED light strips to one PSU, it is essential to use a rated PSU for more watts than a strip lights setup typically require.

- Our power supply must not be rated less than or equal as the total strip light wattage.

- We should use heat recoil over the connectors for protecting them. They are different for outdoor and indoor uses. As an alternate, we may also use insulating or electrical tapes.

- The positive and negative of the strip light should always match with the negative and positive of the connector.

- It is highly recommended that we chalk out a proper plan for our lighting project before purchasing anything for it.

![How to Put LED Lights on TV [4 Easy Steps]](https://colorbrightleds.com/wp-content/uploads/2021/10/LED-Lights-For-TV-2-768x512.jpg)